Benefits of automatic cable recycling

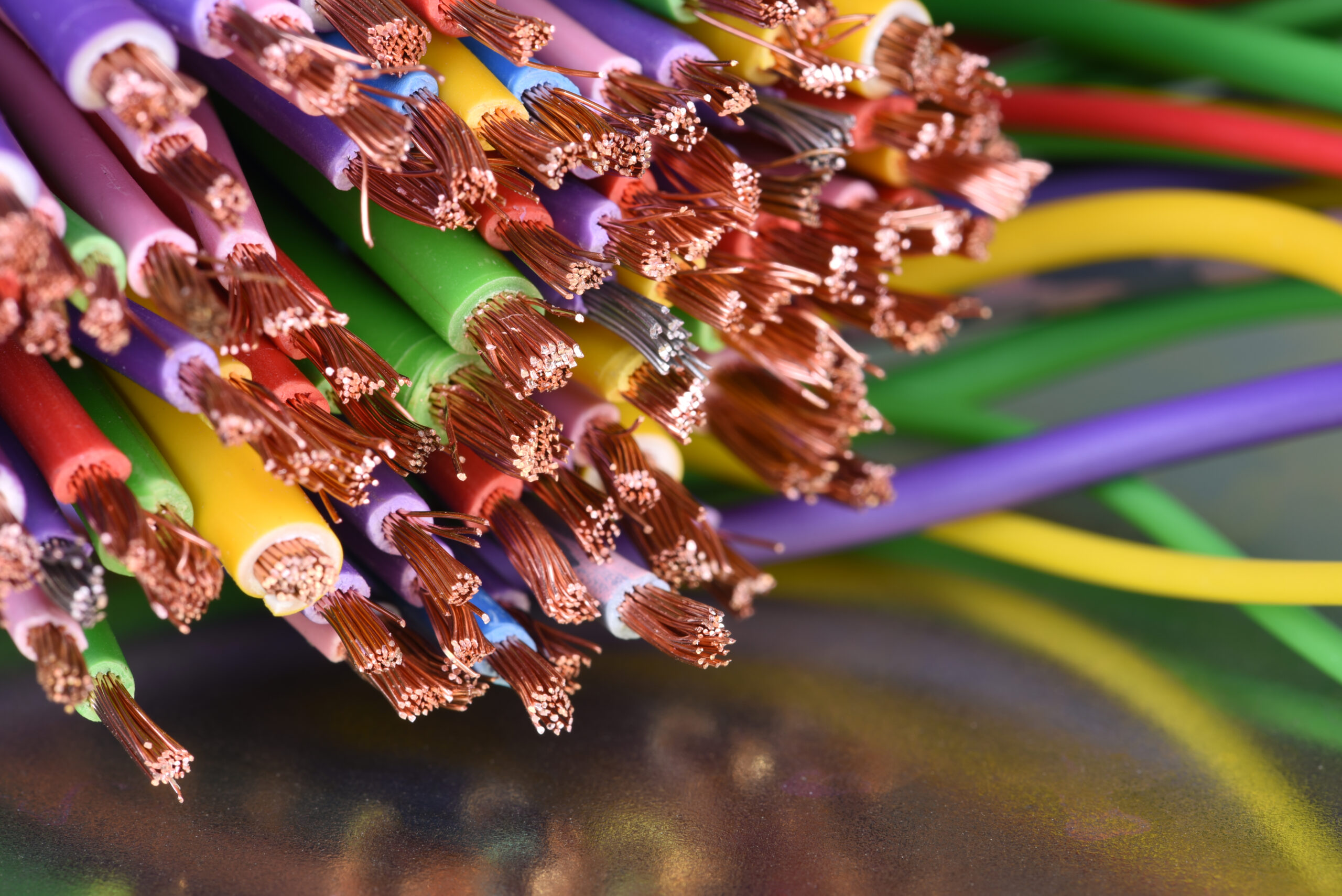

The complexity of processing cable waste lies in their multicomponent composition. One thin cable can contain non-ferrous metals (copper or aluminum), steel sheath, textile and plastic components, polyethylene insulation. Until now, cable scrap is processed, removing only current-carrying cores. However, plastic accounts for up to 45% of cable weight and PVC for up to 70% of all plastic cable components, but these recyclable and reusable materials are simply thrown away. At the same time, not the most environmentally friendly technologies are used:

Winding firing. The cable is fired on an open fire, the insulation burns out, leaving a conductive core. With this processing method, the top layer of metal can melt, and the atmosphere will be replenished with toxic plastic combustion products.

Chemical dissolution of insulation. Copper cables are immersed in a solvent (the type of solvent is selected according to the composition of the jacket), while leaving high purity metal, but high cost, toxicity of solvents, slow performance and the need to constantly renew the solution make this method not the most convenient.

Manual separation of insulation. A complex and slow method, in which the quality of the raw materials obtained leaves much to be desired. It is reasonable to use only with a small amount of raw materials.

Today, using modern technology, it is possible to recycle all types of cables, including very thin, armored, oil-filled, copper and aluminum, underground and underwater laying, high-voltage, coaxial and telephone, electrical wires, extracting all components from waste in the form, suitable for further use. The level of complexity of processing varies depending on the type of cable, but not only non-ferrous metals, but also cable compound using high-tech lines can be extracted without impurities and harm to the environment.

The processing of cable waste is limited by the technological capabilities of enterprises, the productivity of cable processing plants, the cost of work, and the cost of the secondary raw materials obtained. Also, when choosing a recycling technology, the environmental component is important: how safe it will be for humans and nature and how non-threatening for the planet’s ecology the recycled waste will become.

Benefits of our automatic cable recycling

– The accuracy of waste separation reaches 99.9%, the final product is very pure, without impurities, therefore it is more profitable for further sale.

— The use of cable recycling plants gives a positive economic effect: the company saves time and human resources, the dry separation system has low energy consumption, income arises from the sale of separated waste or the reuse of raw materials.

– The resulting processing of copper, aluminum or lead is used to create alloys, and insulation granules are used to produce building materials, road surfaces, packaging, new cables, shoe soles and garden hoses.

— No by-products and wastes, liquids, gases or waste water are generated during the processing. The process is purely physical, no fire, no chemicals, no water, so there is no pollution or waste.

– The volume of cable waste is reduced, we save landfill space, reduce the need to build new landfills, which can become a source of water and air pollution.

– The extraction of non-ferrous metals from the cable takes several times less energy, money and time than their extraction from ore. By recycling copper and aluminum, you reduce the energy consumption of your business.

– Recycling cable waste is your opportunity to contribute to environmental protection, earn money by selling them.

Leave a Reply